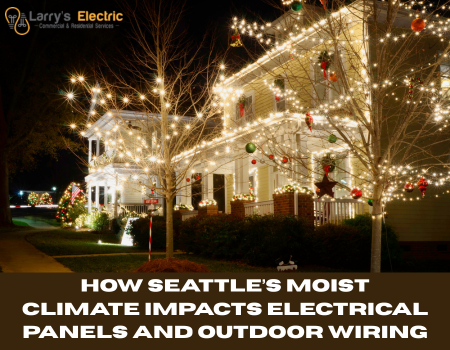

Seattle’s cool, misty weather is part of the city’s charm, but for electrical systems, such as electrical panels and outdoor wiring, it’s a constant threat. With near-year-round moisture, regular rainfall, and long stretches of damp, cloudy days, the Pacific Northwest creates a perfect environment for corrosion, rust, and electrical degradation. Homeowners and commercial property managers in the region are discovering that Seattle’s climate isn’t just inconvenient, it has a direct and often expensive impact on electrical panels and outdoor wiring.

Understanding how moisture affects electrical systems is the first step. The second step is proactive care. As electrical corrosion in Seattle continues to rise, so does the demand for professional inspections, weatherproofing upgrades, and ongoing maintenance.

Why Moisture Is the Silent Enemy of Electrical Panels

Seattle’s climate doesn’t need aggressive storms to cause damage, its steady moisture alone is enough. When humidity lingers and electrical components remain exposed to fluctuating temperatures, condensation begins to form. Even small amounts of moisture can trigger oxidation and rust, slowly compromising wiring, electrical panel parts, and metal enclosures.

Outdoor wiring and panels are especially vulnerable. Corrosion often begins inside screw terminals, breakers, grounding bars, and conduit fittings; areas property owners rarely check. Over time, this hidden damage can cause:

- Tripped breakers

- Frequent power outages

- Reduced system efficiency

- Overheating components

- Fire hazards

These issues tend to appear gradually, which makes them easy to ignore until a major failure occurs. In Seattle, where damp climate wiring issues are common, small signs of moisture damage should never be dismissed.

Electrical Panels: Prime Targets for Moisture Damage

Even indoor electrical panels can suffer in the Pacific Northwest. Many homes and buildings place panels in garages, basements, utility closets, or near exterior walls; all areas prone to condensation and temperature swings.

Moisture affects panels in several ways:

1. Corrosion of Breakers and Bus Bars

When metal components begin to rust, they may no longer conduct electricity properly. Corroded breakers may fail to trip during overloads, creating a serious fire risk.

2. Loose or Degraded Connections

Moisture weakens the contact points between wires and terminals, increasing resistance. High resistance generates heat, and repeated heating and cooling cycles accelerate wear.

3. Internal Condensation

Temperature changes between day and night often create condensation inside panel boxes. Once moisture forms inside, damage spreads quickly, and most property owners never see it happening.

4. Mold and Mildew in Surrounding Areas

In damp environments, mold can grow around or behind electrical panels and electrical equipment. This doesn’t just pose a health issue; it signals persistent moisture exposure that can harm wiring.

Outdoor Wiring: High Risk Year-Round

Outdoor outlets, lighting systems, security wiring, landscape lights, EV chargers, and pool circuits all face direct exposure to Seattle’s moist climate. Rain, fog, dew, and mist can enter aging or improperly sealed components.

The biggest risks include:

- Short circuits caused by water intrusion

- Corroded conduit pipes leading to exposed wires

- Cracked insulation from cold-wet cycles

- Ground faults due to saturated soil

- Failure of GFCIs and outdoor breakers

Many of these issues start small, like a flickering fixture or occasional trip, but indicate water is finding its way into protective housings.

The Importance of Safety Inspections in Seattle

With the rise of electrical corrosion in Seattle, regular inspections are no longer optional. Professionals can identify moisture-related damage long before it becomes dangerous.

A thorough inspection typically includes:

- Checking panels for rust, discoloration, or warm spots

- Testing breakers for proper functionality

- Inspecting conduit for cracks or loose fittings

- Examining outdoor outlets and covers for water intrusion

- Testing GFCIs and AFCIs throughout the property

- Ensuring grounding and bonding meet Washington codes

For many homes and businesses, an annual inspection is the minimum recommended frequency. In coastal or wooded areas with higher humidity, twice a year is becoming standard practice.

Waterproofing and Preventive Maintenance

Proactive protection can dramatically extend the lifespan of electrical panels and systems. Property owners in Washington are increasingly investing in:

Weatherproof Enclosures

Upgraded NEMA-rated boxes keep rain, fog, and condensation out of outdoor panels and wiring.

Corrosion-Resistant Components

Stainless steel hardware, sealed breakers, and moisture-rated wiring reduce long-term degradation.

Proper Ventilation Around Indoor Panels

Improved airflow prevents condensation buildup in basements and garages.

Gasketed Outlet Covers

These prevent water intrusion into outdoor outlets even during heavy rain.

Regular Electrical Panel Maintenance in WA

Cleaning, tightening connections, and replacing early-stage corroded parts reduce the risk of large-scale failure.

Seattle’s climate is beautiful, but tough on electrical systems. Whether it’s gradual corrosion, hidden condensation, or direct water intrusion, moisture causes real and costly problems for panels and outdoor wiring. Without routine inspections and proper waterproofing, property owners face increased fire risks, power failures, and expensive repairs.

Staying ahead of Seattle’s moisture means choosing prevention over reaction. With the right maintenance plan and professional oversight, home and business owners can keep their electrical systems safe, efficient, and protected from the city’s ever-present damp climate.